Premix PRE-ELEC® electrically conductive carbon black compounds provide an effective way to eliminate static electricity making the world more comfortable and safer.

What we experience as an unpleasant electrostatic shock in our everyday life can cause complications and dangerous situations in many industries. Electrostatic shocks also known as electrostatic discharges are created when a charged object, in many cases the plastics, is in contact with another material. The easiest way to prevent the creation of static electricity is to replace the insulating plastic with the conductive one.

Unlike normal plastics, conductive plastics have the ability to conduct electricity. When grounded, the potential energy of conductive plastics remain zero, and they do not accumulate static electricity. Electrically conductive plastics are the right material choice for applications and environments where the risks related to static electricity are present and have to be eliminated. By ensuring that a plastic material is electrically conductive, we can eliminate the problems caused by electrostatic discharge and make the world a more comfortable and safer place for all of us.

Why suffer from problems caused by uncontrolled static electricity if you can solve them easily using ESD control materials?

Uncontrolled electrostatic discharges (ESD) can lead to problems in many industries

Electronics packaging

During the production and transportation of electronics, the uncontrolled electrostatic discharges can cause component failures and breakages. The smaller the electronics component, the more prone it is to static electricity. Today, ESD protection has become even more important, due to the ever-decreasing size of electronics components.

Premix’s conductive and static dissipative plastic compounds protect components from ESD. This will reduce the extent of hidden failures and guarantee a longer operation life for electronic devices.

Explosive atmospheres

In industrial environments, people and environment safety is a key issue when flammable and hazardous liquids, gases and powders are processed, transported and used. Static electricity may lead to problems in different manufacturing and material handling processes. Liquids and powder particles will charge up due to the material’s inner friction and the friction between the particles and the process equipment e.g. pipes, mixers and filters. Electrically conductive PRE-ELEC® compounds and concentrates ensure a safe handling of dusts, powders and liquids also in EX-environments and other explosive atmospheres. Light and corrosion resistant plastics are used for metal replacement, since their processing is easy and cost-efficient.

Hospital and healthcare

In hospital and other healthcare-related environments, static electricity may cause several risks: electrostatic shocks to personnel, electromagnetic interference with equipment, contamination through electrostatic attraction and ignition of flammable agents.

Groundable, electrically conductive and static dissipative plastics are one important mean to minimise and prevent the ESD risks in hospital and other healthcare environments. At Premix, we can improve the safety in the hospital environment by providing, for example, ESD control wheels for hospital beds.

What is the magic behind Premix’s PRE-ELEC® compounds?

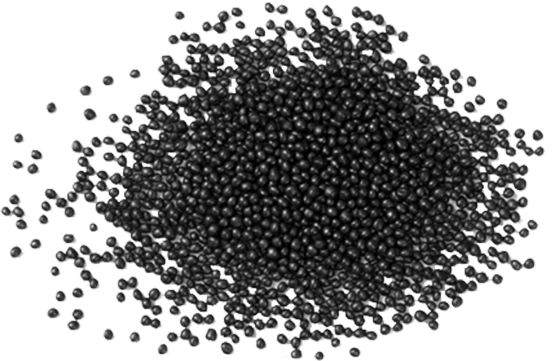

PRE-ELEC® is carbon black magic! Conductive carbon black is the most reliable and cost-efficient choice for producing electrically conductive plastic compounds. The secret behind the perfect carbon black compound lies in three important factors:

- Selecting the optimal carbon black type for the purpose

- Formulating the compound

- Optimising the compounding technique.

Premix’s expertise lies in the formulation and production of functional plastic materials. Let’s make a good mix!

Please contact our Premix specialist Jan Hansson, tel. +46 (0) 703 288 884, if you would like to know more about Premix PRE-ELEC® compounds – the solution to avoid uncontrolled electrostatic discharges.